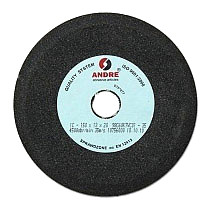

SYMBOLS AND DESIGNATIONS OF GRINDING WHEELS

| Designation of abrasive tool, consistent with the Standard ISO 525, consists of the following groups of alphanumerical characters: | |||

| I group | II group | III group | |

|---|---|---|---|

| type + profile | dimensions | technical characteristics | permissible operating speed (for grinding wheels) |

| In addition, the following additional information, in the form of inscriptions or symbols, may be present on abrasive wheels, segments and sticks: colour strips acc. to speed colour code, safety marks and/or certificate numbers, pictograms, personal protection symbols, instructions, limitations in application, designation, e.g. “STEEL”, “CONCRETE”, “INOX”, “ALUMINIUM”, etc., symbol of static unbalance orientation of grinding wheel or direction for mounting on spindle. | |||

I GROUP - TYPE + PROFILE / DIMENSIONS

Types:

Standard designations for shapes and dimensions of abrasive tools

| Type | Tool | Profile | Dimensions |

|---|---|---|---|

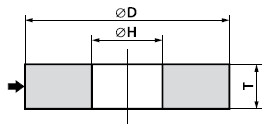

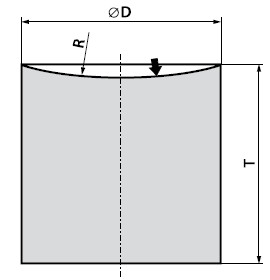

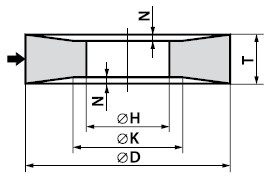

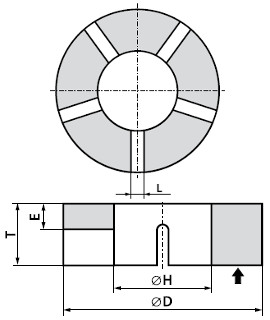

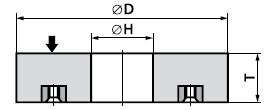

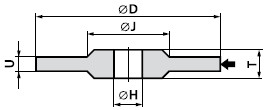

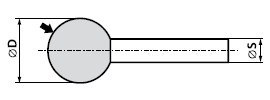

| Type 1 | Straight grinding wheel |  |

1 profile - D × T × H |

| Type 101 |

Wheel for corn hulling machines EKONOS |

|

101 - D x T x H |

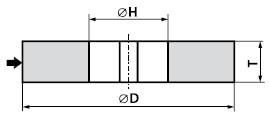

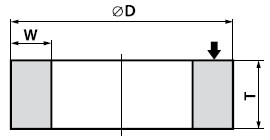

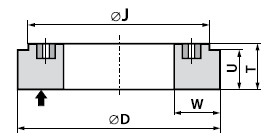

| Type 2 | Cylinder wheel |  |

2 - D × T - W… |

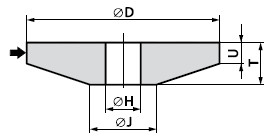

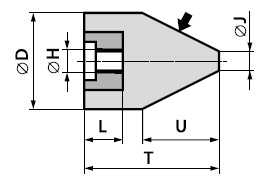

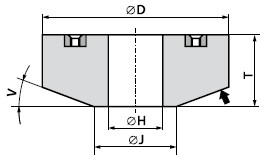

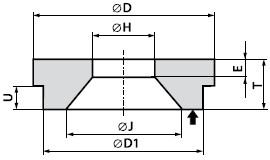

| Type 3 | Wheel tapered on one side |  |

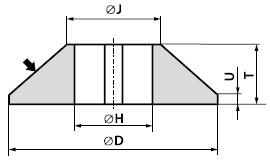

3 - D / J × T / U × H |

| Type 301 | Wheel for corn hulling machines EKONOS |  |

301 - D / J x T / U x H |

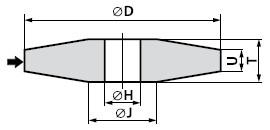

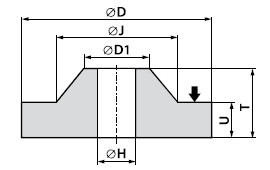

| Type 4 | Wheel tapered on both sides |  |

4 - D / J × T / U × H |

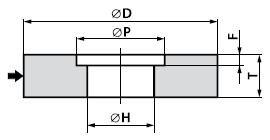

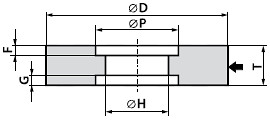

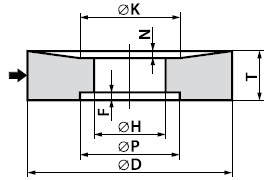

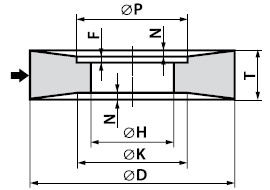

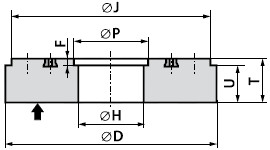

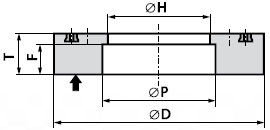

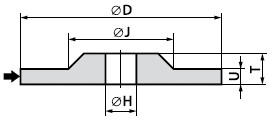

| Type 5 | Wheel recessed on one side |  |

5 profile- D × T × H - P…F… |

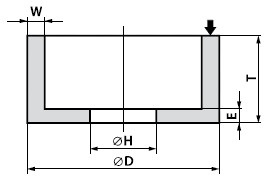

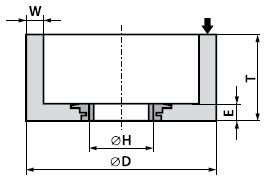

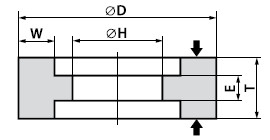

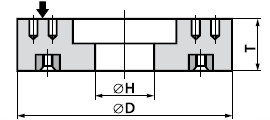

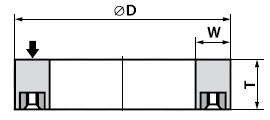

| Type 6 | Straight cup wheel |  |

6 - D × T × H - W…E… |

| Type 6001 | Straight cup wheel with a central threaded insert |  |

6001 - D × T × H - W…E… |

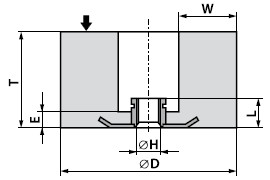

| Type 6002 | Straight cup wheel with a central threaded insert |  |

6002 - D × T × H / L - W...E… |

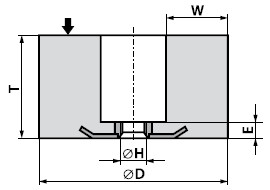

| Type 6003 | Straight cup wheel with a central threaded insert |  |

6003 - D × T × H - W…E… |

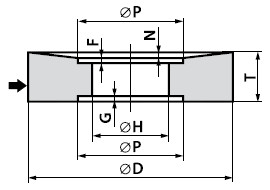

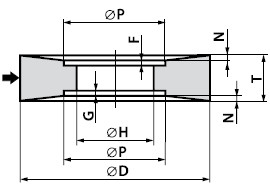

| Type 7 | Wheel recessed on both sides |  |

7 zarys - D × T × H - P…F…G… |

| Type 9 | Double cup wheel |  |

9 - D × T × H - W…E… |

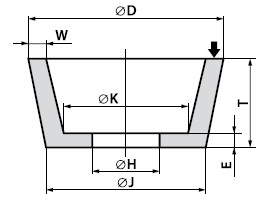

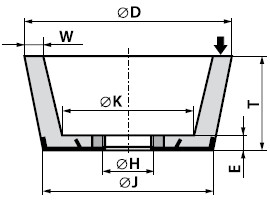

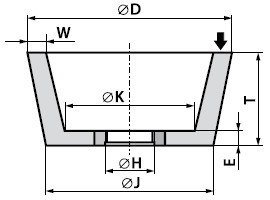

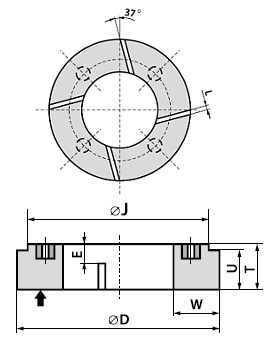

| Type 11 | Taper cup wheel |  |

11 - D / J × T × H - W…E…K… |

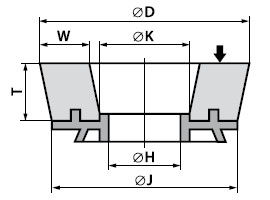

| Type 1102 | Taper cup wheel with a spiral for a quick change mounting |  |

1102 - D / J × T × H - W…K… |

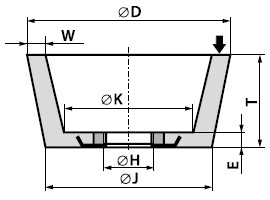

| Type 1112 | Taper cup wheel with a central threaded insert |  |

1112 - D / J × T × H - W…E…K… |

| Type 1113 | Taper cup wheel with a central threaded insert |  |

1113 - D / J × T × H - W…E…K… |

| Type 1114 | Taper cup wheel with a central threaded insert |  |

1114 - D / J × T × H - W…E…K… |

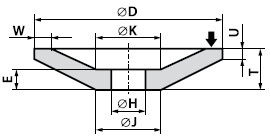

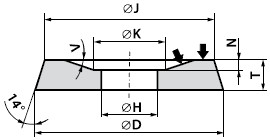

| Type 12 | Dish wheel |  |

12 - D / J × T / U × H - W…E…K… |

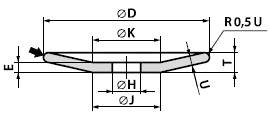

| Type 13 | Saucer wheel |  |

13 - D / J × T / U × H - E…K… |

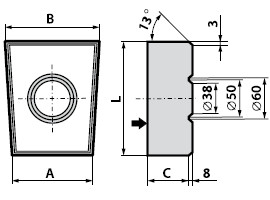

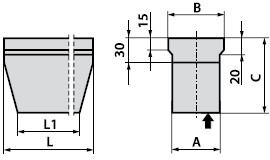

| Type 16 | Cones and plugs, tapered roll shaped, with a threaded insert |  |

16 - D × T - H × L |

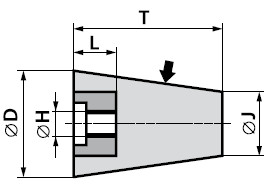

| Type 17 | Cones and plugs, tapered |  |

17 - D / J × T - H × L |

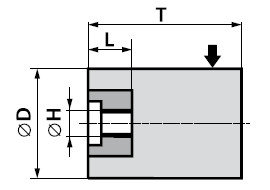

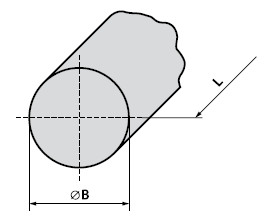

| Type 18 | Cones and plugs, cylindrical |  |

18 - D × T - H × L |

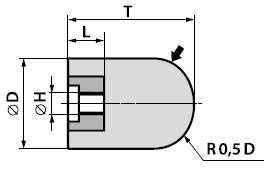

| Type 18R | Cones and plugs, roll shaped with a threaded insert |  |

18R - D × T - H × L |

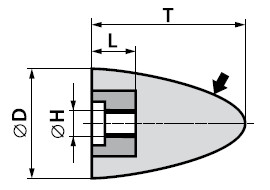

| Type 1801 | Cylindrical wheel with spherical working surface |  |

1801 - D × T - R… |

| Type 19 | Cones and plugs, cylinder-conical with a threaded insert |  |

19 - D / J × T / U - H × L |

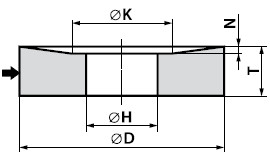

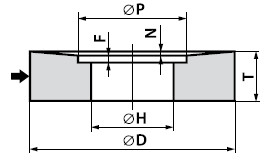

| Type 20 | Wheel relieved on one side |  |

20 - D / K × T / N × H |

| Type 2001 | Special shape wheel for vegetable pulp mills |  |

2001 - D / J × T × H - V - nr rysunku |

| Type 21 | Wheel conically relieved on both sides |  |

21 - D / K × T / N × H |

| Type 22 | Wheel conically relieved on one side and recessed on the other side |  |

22 - D / K × T / N × H - P… F… |

| Type 23 | Wheel relieved and recessed on one side |  |

23 - D × T / N × H - P…F… |

| Type 24 | Wheel relived, recessed on one side and recessed on the other side |  |

24 - D × T / N × H - P…F…G… |

| Type 25 | Wheel relieved, recessed on one side and relieved on the other side |  |

25 - D / K × T / N × H - P…F… |

| Type 26 | Wheel relieved and recessed on both sides |  |

26 - D × T / N × H - P… F…G… |

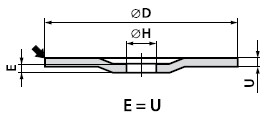

| Type 27 | Depressed centre wheel |  |

27 - D × U × H |

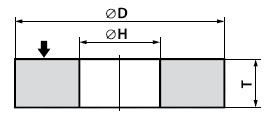

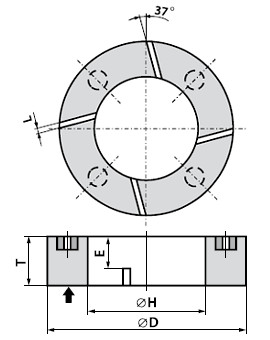

| Type 35 | Disc wheel |  |

35 - D × T × H |

| Type 3501 | Disc wheel with slots |  |

3501 - D × T / E × H - L…n… n - number of slots |

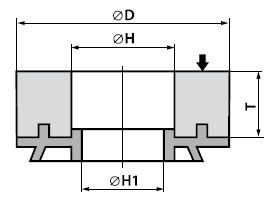

| Type 3502 | Disc wheel with a spiral for quick-change mounting |  |

3502 - D × T × H / H1 |

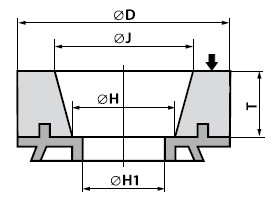

| Type 3503 | Tapered wheel with a spiral for quick-change mounting |  |

3503 - D / J × T × H / H1 |

| Type 3504 | Wheel relieved on one side and with slots on the opposite side |  |

3504 - D / J × T / U / E × H - L…n… n - number of slots |

| Type 36 | Disc wheel with threaded inserts |  |

36 - D × T × H - drawing no. |

| Type 3601 | Disc wheel with threaded inserts and with perforation holes on the working side |  |

3601 - D × T × H - drawing no. |

| Type 3603 | Wheel with threaded inserts, relieved on the clamping side |  |

3603 - D × T × H - drawing no. |

| Type 3610 | Wheel with threaded inserts and incisions |  |

3610 - D × T × H - drawing no. |

| Type 3611 | Taper wheel with threaded inserts |  |

3611 - D × T × H - drawing no. |

| Type 3612 | Taper wheel with threaded inserts, recessed on the working side |  |

3612 - D × T × H - drawing no. |

| Type 37 | Cylinder wheel with threaded inserts |  |

37 - D × T - W… - drawing no. |

| Type 3701 | Cylinder wheel with threaded inserts, relieved on one side and with slots on the opposite side |  |

3701 - D × T - W… - drawing no. |

| Type 3703 | Cylinder wheel with threaded inserts, relieved on one side |  |

3703 - D × T - W… - drawing no. |

| Type 38 | Hubbed wheel |  |

38 profile - D / J × T / U × H |

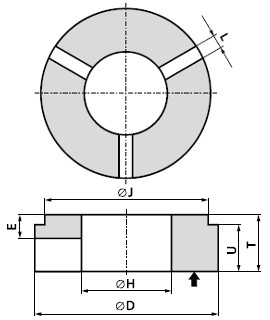

| Type 3801 | Wheel with special shape intended for rubbing through of vegetable pulp |  |

3801 - D / J × T / U × H - drawing no. |

| Type 3802 | Wheel with special shape intended for rubbing through of vegetable pulp |  |

3802 - D / J × T / U × H - drawing no. |

| Type 39 | Double hubbed wheel |  |

39 profile - D / J × T / U × H |

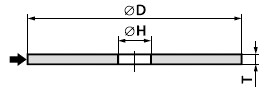

| Type 41 | Straight cutting-off wheel |  |

41 - D × T × H |

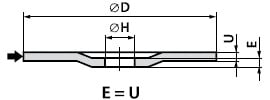

| Type 42 | Depressed center cutting-off wheel |  |

42 - D × U × H |

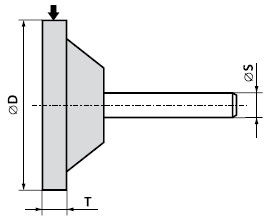

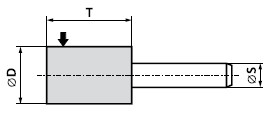

| Type 5201 | Mounted point, flat with a conical reinforcement |  |

5201 - D × T × S |

| Type 5210 | Mounted point, cylindrical |  |

5210 - D × T × S |

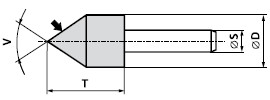

| Type 5211 | Mounted point, cylindrical with conical end |  |

5211 - D × T × S - V |

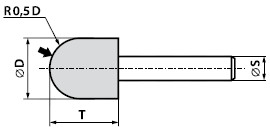

| Type 5213 | Mounted point, cylindrical with rounded end |  |

5213 - D × T × S |

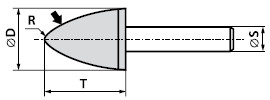

| Type 5220 | Mounted point, ogival shape |  |

5220 - D × T × S - R… |

| Type 5230 | Mounted point, spherical |  |

5230 - D × S |

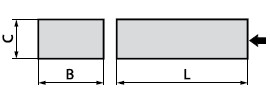

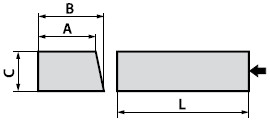

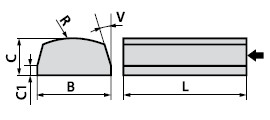

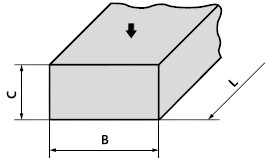

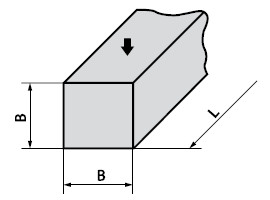

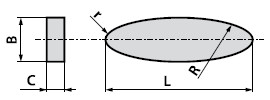

| Type 3101 | Segment, rectangular |  |

3101 - B × C × L |

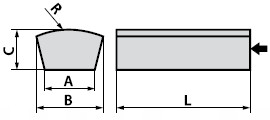

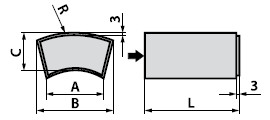

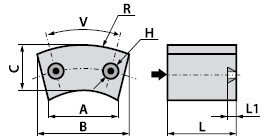

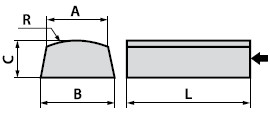

| Type 3103 | Segment, trapezoidal with outside radius |  |

3103 - B / A × C × L - R… |

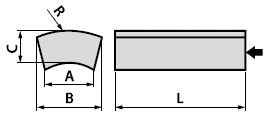

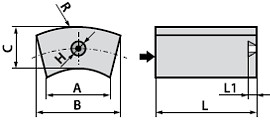

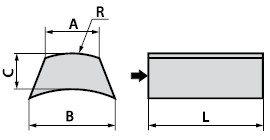

| Type 3104 | Segment, with inner and outer radius |  |

3104 - B / A × C × L - R… |

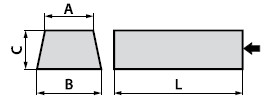

| Type 3108 | Segment, rectangular-trapezoidal |  |

3108 - B / A × C × L |

| Type 3109 | Segment, trapezoidal |  |

3109 - B / A × C × L |

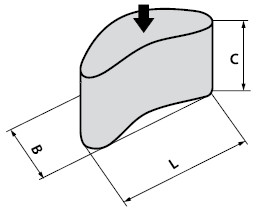

| Type 3110 | Segment, kidney-shaped |  |

3110 - B × C × L |

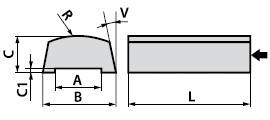

| Type 3113 | Segment, with outer and inner radius and recess |  |

3113 - B / A × C / C1 × L - R…V… |

| Type 3114 | segment, rectangular, ring-shaped, chamfered on both sides |  |

3114 - B × C / C1 × L - R…V… |

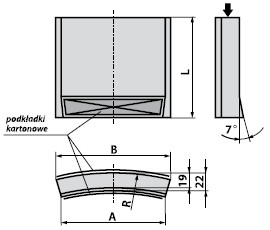

| Type 3115 | Full segment, ring-shaped, DISCUS Type |  |

3115 - B / A × C × L - R… |

| Type 3116 | Full segment, ring-shaped, DISCUS type, with a threaded insert |  |

3116 - B / A × C × L - R… - H / L1 |

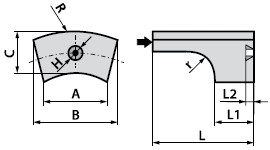

| Type 3117 | Segment, DISCUS type, recessed, with a threaded insert |  |

3117 - B / A × C × L / L1 - R…r… - H / L2 |

| Type 3118 | Segment, shaped, DISCUS type |  |

3118 - B / A × C × L |

| Type 3119 | Segment, with outer and inner radius and with two threaded inserts |  |

3119 - B / A × C × L - R… - H / L1 / V |

| Type 3120 | Segment, shaped for rail grinding |  |

3120 - B / A × C × L / L1 |

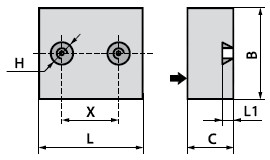

| Type 3121 | Segment, rectangular with two threaded inserts |  |

3121 - B × C × L - H / X / L1 |

| Type 3122 | Segment, taper with outer radius |  |

3122 - B / A × C × L - R… |

| Type 3123 | Segment, ring-shaped, chamfered |  |

3123 - B / A × L - R… |

| Type 3124 | Segment, taper with inner and outer radius |  |

3124 - B / A × C × L - R… |

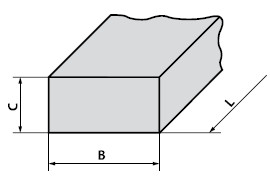

| Type 5410 | Wheatstone, rectangular |  |

5410 - B x C x L |

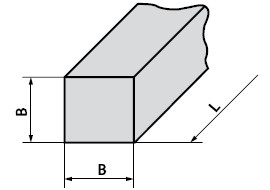

| Type 5411 | Wheatstone, square |  |

5411 - B x L |

| Type 9010 | Wheatstone, rectangular |  |

9010 - B x C x L |

| Typee 9011 | Wheatstone, square |  |

9011 - B x L |

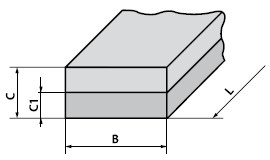

| Type 9020 | Wheatstone, rectangular, two-layered |  |

9020 - B x C / C1 x L |

| Type 9030 | Wheatstone, round |  |

9030 - B x L |

| Type 9050 | Wheatstone, oval |  |

9050 - B x C x L - R...r... |

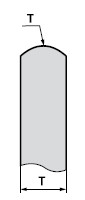

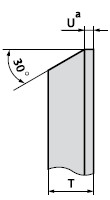

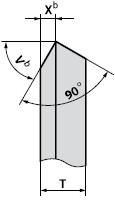

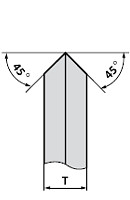

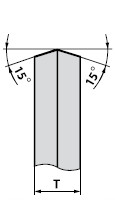

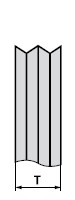

Profiles:

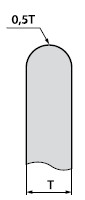

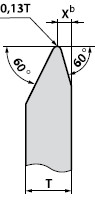

| Profile | A | B | C | D | E |

|---|---|---|---|---|---|

| Shape |  |

|

|

|

|

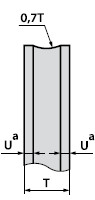

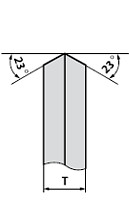

| Profile | F | G | H | I | J |

| Shape |  |

|

|

|

|

| Profile | K | L | M | N | P |

| Shape |  |

|

|

|

|

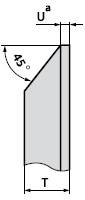

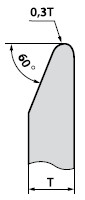

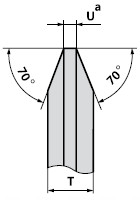

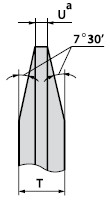

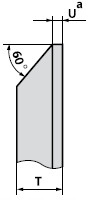

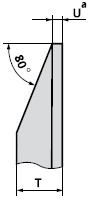

| Profile | Q | R | S | T | U |

| Shape |  |

|

|

|

|

| Profile | W | X | a) U = 3,2 [mm] unless otherwise ordered b) V and X values need to be specified with order Pofile X is non-standardized, can me made to drawing delivered by the customer |

||

| Shape |  |

|

|||

II GROUP - CHARACTERISTICS

| Characteristics | 1. Abrasive material | 2. Grain size | 3. Hardness grade of abrasive tool | 4. Structure | 5. Bond |

|---|---|---|---|---|---|

| Example | 95A | 80 | R | 5 | BF |

1. Abrasive Materials:

| Type | Nature |

|---|---|

| Normal (brown) amulinium oxide | 95A |

| Friable aluminium oxide | 99A |

| Semifriable aluminium oxide | 97A |

| Pink aluminium oxide | CrA |

| Zirconia aluminium oxide | ZrA |

| Monorocundum | M |

| Monocrystaline aluminium oxide | X |

| Combinations of aluminium oxides | 50A do 98A |

| Green silicon carbide | 99C |

| Black silicon carbide | 98C |

| Combinations of silicon carbides | 50C |

| Combinations of aluminium oxides and silicon carbides | 50AC do 55AC |

2. Grain size of abrasive material:

| Macrograins | Micrograins | ||

|---|---|---|---|

| Coarse | Medium | Fine | Very fine |

| 4 | 30 | 70 | 230 |

| 5 | 36 | 80 | 240 |

| 6 | 40 | 90 | 280 |

| 7 | 46 | 100 | 321 |

| 8 | 54 | 120 | ... |

| 10 | 60 | 150 | |

| 12 | 180 | ||

| 14 | 220 | ||

| 16 | |||

| 20 | |||

| 22 | |||

| 24 | |||

3. Hardness grade of abrasive tool

| Hardness grade | |

|---|---|

| E F G | Very soft |

| H I J K | Soft |

| L M N O | Medium |

| P Q R S | Hard |

| T U V W X Y Z | Very hard |

4. Structure:

May be missing in designation.

| Closed | Medium | Open | Porous |

|---|---|---|---|

| 2 | 5 | 9 | 8 |

| 3 | 6 | - | 12 |

| 4 | 7 | - | - |

| - | 8 | - | - |

5. Bond:

| Type | Nature (manufacturer's symbol) |

|---|---|

| V - vitrified bond | VE01, VE01P, VC01, VC01P, VTE10;14;16, VTE10P, VTC10;12, VTC10P |

| B - resinoid bond | B51, B51F, B305, B374 |

| BF - resinoid bond, reinforced |

GROUP III - MAXIMUM PERMISSIBLE PERIPHERAL SPEED

| Grinding wheels with vitrified bond "V" | Grinding wheels with resinoid bond "B" and "BF" | |

|---|---|---|

| Conventional speeds | v ≤ 25, 32, 35 (40, 45) [m/s] | v ≤ 35, 40, 50 [m/s] |

| Increased speeds | v ≤ 40, 50 [m/s] | v ≤ 63 [m/s] |

| High speeds | v ≤ 63, 80 [m/s] | v ≤ 80, 100 [m/s] |

ABRASIVE MATERIALS

| Aluminum oxide (synthetic corundum) - αAl2O3 | ||

|---|---|---|

| Aluminum oxide in different variations is the most frequently used abrasive material. It is melted from bauxite or aluminium oxide at temp. over 2000° C in electric furnaces. | ||

| 95A - Normal aluminium oxide (brown) |

It is prepared from bauxite. Contains 95% Al2O3, ~ 3% titanium dioxide (TiO2) oraz ~1-2% other admixtures. It is the most resistant synthetic corundum and is characterized by its high ductility. It is used for cutting-off and rough grinding of low-alloy steels, stainless steels, cast iron, especially for high rates of stock removal. |  |

| 97A - Semifriable aluminium oxide (grey) |

It is prepared from calcinated bauxite with aluminium oxide addition. Contains 97% Al2O3 corundum and is characterized by medium hardness and strength. It is used for precision grinding and tool grinding. |  |

| 99A - Friable aluminium oxide (white) |

It is prepared from pure aluminium oxide. It is the purest synthetic corundum and contains over 99% Al2O3. It is characterized by its high hardness and brittleness. It is used for precision grinding, e.g. surface and cylindrical grinding, sharpening of cutting tools. |  |

| CrA - Chromium aluminium oxide (pink) |

It is prepared from aluminium oxide with an addition of up to several percent of chromium oxide. It is characterized by its high hardness and higher strength in comparison with white aloxite. It is used for precision grinding of high-alloy steels, sharpening of cutting tools. |

|

| M - Monocorundum (grey) |

It is prepared from bauxite by reduction process. Contains over 99% Al2O3. It is characterized by its high microhardness and mechanic strength and has an excellent self-sharpening ability. It is used for grinding of high-alloy high-speed steels and sharpening of tools. Excellent for grinding of complex profiles. |  |

| ZrA - Zirconia aluminium oxide |

It is prepared from aluminium oxide or bauxite with an addition of zirconium dioxide. It is characterized by the highest microhardness and mechanic strength among other aloxities. It is used for highly efficient grinding of cast iron, grinding of steel semiproducts using high pressures. |  |

| Silicon carbide (carborundum) - SiC. | ||

|

Prepared from high-silica sand of high purity and petroleum coke in resistance furnaces using the synthesis process. The second, after diamond, in respect to hardness. |

||

| 99C - Green silicon carbide |

High purity silicon carbide is green and contains 99% SiC min. It is used for grinding of sintered carbides, ceramics, stones, sharpening of cutting tools with sintered carbide inserts. |  |

| 98C - Black silicon carbide |

Contains 98% SiC and more amount of admixtures. Similarly to 99C, it is used for grinding of sintered carbides, ceramic materials, concrete, stone, rough grinding of castings (fettling) made of hard and fragile white cast iron and for cutting of concrete, stone and white cast iron. |  |

Grain sizes in accordance with FEPA 42-D-1984 and PN/M-59107 standards:

| Makroziarna | Mikroziarna | ||||

|---|---|---|---|---|---|

| FEPA designation | Mean size of grain [mm] | FEPA designation | Mean size of grain [mm] | FEPA designation | Mean size of grain [mm] |

| F4 | 5,600 - 4,750 | F30 | 0,600 - 0,500 | F230 | 56,0 - 50,0 |

| F5 | 4,750 - 4,000 | F40 | 0,500 - 0,425 | F240 | 46,5 - 42,5 |

| F6 | 4,000 - 3,350 | F46 | 0,425 - 0,355 | F280 | 38,5 - 35,0 |

| F7 | 3,350 - 2,800 | F54 | 0,355 - 0,300 | F320 | 30,7 - 27,7 |

| F8 | 2,800 - 2,360 | F60 | 0,300 - 0,250 | F360 | 24,3 - 21,3 |

| F10 | 2,360 - 2,000 | F70 | 0,250 - 0,212 | F400 | 18,3 - 16,3 |

| F12 | 2,000 - 1,700 | F80 | 0,212 - 0,180 | F500 | 13,8 - 11,8 |

| F14 | 1,700 - 1,400 | F90 | 0,180 - 0,150 | F600 | 10,3 - 8,3 |

| F16 | 1,400 - 1,180 | F100 | 0,150 - 0,125 | F800 | 7,5 - 5,5 |

| F20 | 1,180 - 1,000 | F120 | 0,125 - 0,106 | F1000 | 5,3 - 3,7 |

| F22 | 1,000 - 0,850 | F150 | 0,106 - 0,075 | F1200 | 3,5 - 2,5 |

| F24 | 0,850 - 0,710 | F180 | 0,090 - 0,063 | ||

| F30 | 0,710 - 0,600 | F220 | 0,075 - 0,053 | ||

PICTOGRAMS - SAFETY SYMBOLS

|

Wear ear protection | |

|

Use eye protection | |

|

Use protection of respiratory system | |

|

Wear protective and antivibration gloves | |

|

Follow work instructions and safety regulations | |

|

Application: side (peripheral) grinding | |

|

Limitations in application “not allowed for side grinding” | |

| Colour strip - additional visual information on maximum permissible operating speed in accordance with colour code (from EN 12413). | ||

|---|---|---|

| Maximum permissible peripheral speed [ms-1] | No. of strips and colour | |

| 50 | 1 x blue | |

| 63 | 1 x yellow | |

| 80 | 1 x red | |

| 100 | 1 x green | |