Indexable Insert Chipbreaker Cross Reference

Note: Chart is intended to be used as a guide to chipbreaker selections. The information listed is approximate and all specific information should be obtained from the manufacturers.

Kennametal, Seco, Valenite, Iscar, Sumitomo, Stellram, Hertel & Interstate are currently represented in the MSC Big Book.

| Operation | Kennemetal | Sandvik | Seco | Walter-Valenite | Iscar | Hertel | Sumitomo | Stellram | Mitsubishi | Tungaloy | Interstate | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Fine Finishing |

FF |

PF |

MF2 |

C5, F2 |

RF,FF |

BF,HF,BFM |

ESU |

1A, 62 |

SH |

TS, TSF |

IF, P |

|

|

Fine Finishing |

UF |

UF, QF |

FF1 |

PS5 |

SF, SM |

HF, CFM |

ESU, ESX |

-62 |

FV, FW |

1, TSF |

||

|

Finishing |

LF |

PF |

F1 |

F5, PF2, PF4 |

NF |

AF, AM, LF, HMF |

ESU, ESP, ESX |

-62 |

FV,FS MQ |

PS |

2C |

|

|

Finishing |

LF |

MF,-23 |

MF1 |

F5, NF3, NF4 |

TF |

AF, AM, LF, HMF |

EGU, ESX, EUX |

3F |

SH |

TM |

||

|

Finishing |

FP |

MF1 |

F5 |

PP |

F, HF, HMF |

EGU, ENK |

2B |

SH |

||||

|

Finishing |

FN |

PF |

MF2 |

PF4 |

PP |

F, HMF, AMF |

EGU, ESU, ESX |

1A |

SA |

TS |

||

|

Finishing |

MP-K |

MF5 |

M4, M5 |

TF, GN |

F |

EGU, EUX, ENK |

3J |

MS, MV |

||||

|

Medium Machining |

CT |

44 |

IMF | |||||||||

|

Medium Machining |

MP |

MF |

MF3 |

M5 |

TF |

HMF, HM, M2 |

EUX, EGU, EUP |

1A |

MS, SA |

SS |

KC |

|

|

Medium Machining |

MS |

M1 |

M2, PM2 |

VL |

L3, HL1, L4, M1 |

EUP |

CM |

HF |

||||

|

Medium Machining |

MN |

PM |

M2 |

M3 |

GN |

HM, M2 |

EGE, EUP. EUX |

2N |

MS |

CM, TM |

MM |

|

|

Medium Machining |

MN |

PM |

M3 |

PM4, PM5, NM9 |

TNM |

HM, M2 |

EGU, EMU, ENG |

2N |

MA |

TM |

IMR |

|

|

Medium Machining |

MN |

QM |

M5 |

NM4, NM5, NM6 |

NR, TNM |

HM, M2 |

EGU, EMU, ENG |

4T |

MA |

TH |

||

|

Medium Machining |

P |

2C, 73 |

MR3 |

F5, C5 |

GN |

HM, L5, L6, M1, |

ESE, EGU, EMU, ENG, ENZ |

2C, 73 |

MP |

SA |

||

|

Medium Machining |

GP |

-23 |

M1 |

M2, F5 |

PP |

EMU, ENZ 3J MS PP, TH |

||||||

|

Medium Machining |

UP |

M3 |

55, |

M5

GN |

M2 EMU, ENZ |

MF5 |

GJ, MV |

TH |

||||

|

Roughing |

RP |

QM |

MR3 |

NR4 |

NP |

HM, HRM, R |

EMU, EGE, ENZ |

2N |

MH |

TR |

IR, 55 |

|

|

Roughing |

RP |

QM |

MR4 |

NR4 |

RP |

HRM, R |

EMX, ENZ |

4M |

MH |

TH |

||

|

Roughing |

UN |

PR |

M5,MR7 |

R3 |

TNM |

HR, HMR, HRM, HRR, R |

ENZ, EMU |

3M |

GH |

TU |

||

|

Roughing |

RN |

MR |

MR5 |

R3 |

NR |

HR, HMR, HRM, HRR, R |

EMU, EGE |

5V |

MH |

SS |

||

|

Roughing |

RN |

PR |

MR4 |

R3 |

NR |

HR, HMR, HRM, HRR, R |

EMX |

5V |

GH |

TU |

||

|

Heavy Roughing (Single Sided) |

RH |

HR |

R8 |

NR4 |

RP |

R10 |

EHG |

4M |

HV |

TR |

||

|

Heavy Roughing (Single Sided) |

RH |

HR |

RR9 |

RP4 |

RP |

R25,R25Z |

ENP |

4M |

HV |

TR |

||

|

Heavy Roughing (Single Sided) |

RM |

PR |

R4 |

RP4 |

-12 |

Q8 |

EHG |

5V |

HA |

TU |

||

|

Heavy Roughing (Single Sided) |

RM |

PR |

R6 |

NM |

R75,R75Z |

ENP |

4M |

HA |

-65 |

|||

|

Heavy Roughing (Single Sided) |

RM |

HR |

R7 |

NM |

EHP |

4M |

HV |

-65 |

||||

Insert Designation (ISO CODE)

| 1. | 2. | 3. | 4. | 5. | 6. | 7. | - | 8. | 9. | |

|---|---|---|---|---|---|---|---|---|---|---|

| Designation | Insert shape and angle | Normal clearance angle | Tolerance class | Chipbreaker and clamping type | Edge length | Insert thickness | Corner radius / finishing edge | Cutting edge condition | Cutting direction | |

| Example | C | N | M | G | 12 | 04 | 08 | - | E | N |

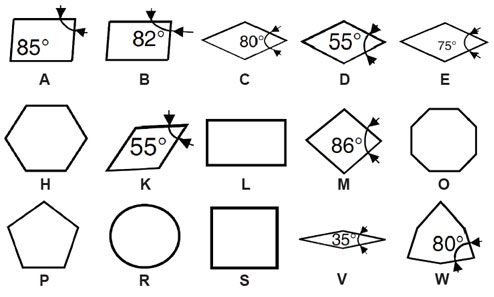

1. Insert shape and angle

2. Normal clearance angle

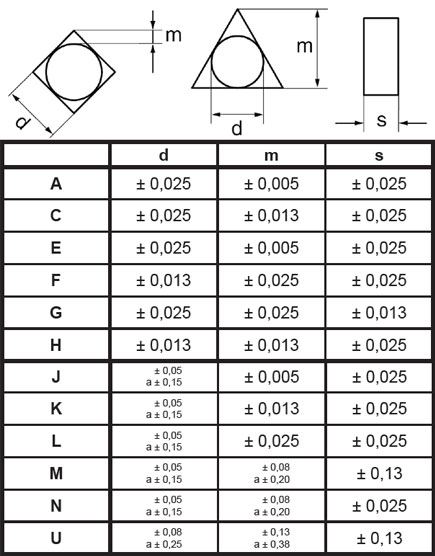

3. Tolerance class

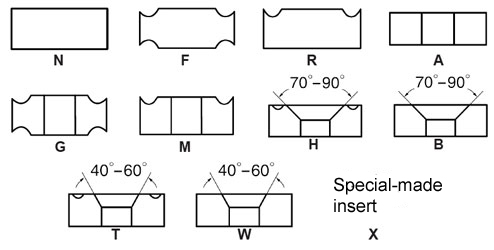

4. Chipbreaker and clamping style

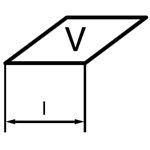

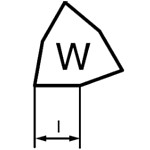

5. Cutting edge length

|

|

|

|

|

|

|

|

l, d | |

| mm | cale | |||||||

| S4 | 04 | 03 | 03 | 06 | - | - | 3,97 | 5/32 |

| 04 | 05 | 04 | 04 | 08 | 08 | S3 | 4,76 | 3/16 |

| 05 | 06 | 05 | 05 | 09 | 09 | 03 | 5,56 | 7/32 |

| - | - | 06 | - | - | - | - | 6,00 | .236 |

| 06 | 07 | 06 | 06 | 11 | 11 | 04 | 6,35 | 1/4 |

| 08 | 09 | 07 | 07 | 13 | 13 | 05 | 7,94 | 5/16 |

| - | - | 08 | - | - | - | - | 8,00 | .315 |

| 09 | 11 | 09 | 09 | 16 | 16 | 06 | 9,52 | 3/8 |

| - | - | 10 | - | - | - | - | 10,00 | .394 |

| 11 | 13 | 11 | 11 | 19 | 19 | 07 | 11,11 | 7/16 |

| - | - | 12 | - | - | - | - | 12,00 | .472 |

| 12 | 15 | 12 | 12 | 22 | 22 | 08 | 12,70 | 1/2 |

| 14 | 17 | 14 | 14 | 24 | 24 | 09 | 14,29 | 9/16 |

| 16 | 19 | 15 | 15 | 27 | 27 | 10 | 15,88 | 5/8 |

| - | - | 16 | - | - | - | - | 16,00 | .630 |

| 17 | 21 | 17 | 17 | 30 | 30 | 11 | 17,46 | 11/16 |

| 19 | 23 | 19 | 19 | 33 | 33 | 13 | 19,05 | 3/4 |

| - | - | 20 | - | - | - | - | 20,00 | .787 |

| 22 | 27 | 22 | 22 | 38 | 38 | 15 | 22,22 | 7/8 |

| - | - | 25 | - | - | - | - | 25,00 | .984 |

| 25 | 31 | 25 | 25 | 44 | 44 | 17 | 25,40 | 1 |

| 32 | 38 | 31 | 31 | 54 | 54 | 21 | 31,75 | 1 1/4 |

| - | - | 32 | - | - | - | - | 32,00 | 1.260 |

6. Insert thickness

| Symbol | Thickness[mm] |

|---|---|

| 01 | 1,59 |

| T1 | 1,98 |

| 02 | 2,38 |

| 03 | 3,18 |

| T3 | 3,97 |

| 04 | 4,76 |

| 06 | 6,35 |

| 07 | 7,94 |

| 08 | 8,00 |

| 09 | 9,52 |

| 12 | 12,70 |

7. Corner radius / Finishing edge

| Symbol | Corner radius r |

|---|---|

| 02 | 0,2 |

| 04 | 0,4 |

| 08 | 0,8 |

| 12 | 1,2 |

| 16 | 1,6 |

| 20 | 2,0 |

| 24 | 2,4 |

| 32 | 3,2 |

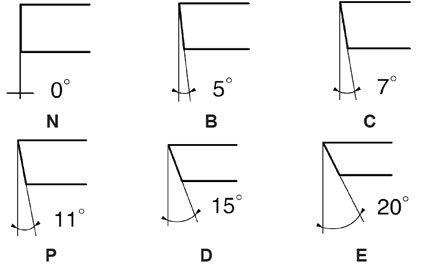

| Symbol | Insert's clearance angle Κr | Symbol | Finishing edge's normal clearance angle αn |

|---|---|---|---|

| A | 45° | A | 3° |

| D | 60° | B | 5° |

| E | 75° | C | 7° |

| F | 85° | D | 15° |

| P | 90° | E | 20° |

| Z | inny kąt | F | 25° |

| G | 30° | ||

| N | 0° | ||

| P | 11° | ||

| Z | inny kąt |

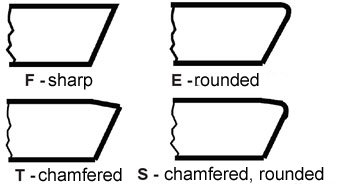

8. Cutting edge condition

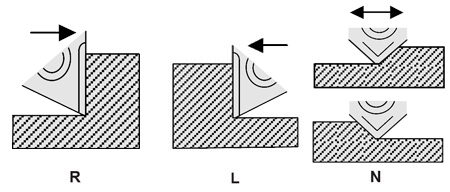

9.Cutting direction

Basic cutting conditions - TURNING

| Material group | Material group No | Brinell hardness [HB] | Corner radius 04 | Cordner radius 08 | Corner radius 12 | Vc [m/min] | |||

|---|---|---|---|---|---|---|---|---|---|

| ap | f | ap | f | ap | f | ||||

| Low carbon steel | 1 | 150 | 0,50 - 1,50 | 0,10 - 0,15 | 1,00 - 3,00 | 0,22 - 0,28 | 1,50 - 5,00 | 0,35 - 0,50 | 350 |

| 180 | 280 | ||||||||

| 210 | 250 | ||||||||

| Alloy steel | 2 | 180 | 0,50 - 1,50 | 0,10 - 0,12 | 1,00 - 3,00 | 0,22 - 0,28 | 1,50 - 4,00 | 0,32 - 0,45 | 270 |

| 230 | 230 | ||||||||

| 280 | 190 | ||||||||

| 320 | 170 | ||||||||

| High aloyt steel | 3 | 220 | 0,50 - 1,50 | 0,10 | 1,00 - 3,00 | 0,20 - 0,25 | 1,50 - 3,00 | 0,30 - 0,42 | 170 |

| 280 | 130 | ||||||||

| 320 | 110 | ||||||||

| 350 | 90 | ||||||||

| Austenic stainless steel | 4 | 210 - 250 | 0,50 - 1,50 | 0,12 - 0,15 | 1,00 - 3,00 | 0,18 - 0,32 | 1,50 - 5,00 | 0,35 - 0,52 | 230 |

| 5 | 230 - 270 | 0,50 - 1,50 | 0,10 - 0,12 | 1,00 - 3,00 | 0,18 - 0,25 | 1,50 - 4,00 | 0,32 - 0,48 | 190 | |

| 6 | - | 0,50 - 1,20 | 0,11 | 1,00 - 1,25 | 0,18 - 0,23 | 1,50 - 3,00 | 0,30 - 0,45 | 110 | |

| Ferritic stainless steel | 7 | annealed | 0,50 - 1,50 | 0,12 - 0,15 | 1,00 - 3,00 | 0,22 - 0,28 | 1,50 - 4,00 | 0,32 - 0,48 | 190 |

| Martensitic stailness stell | 8 | annealed | 0,50 - 1,50 | 0,12 - 0,15 | 1,00 - 3,00 | 0,22 - 0,28 | 1,50 - 4,00 | 0,32 - 0,48 | 190 |

| treated | 150 | ||||||||

| Grey cast iron | 9 | 140 - 250 | 0,20 - 1,50 | 0,08 - 0,15 | 1,00 - 4,00 | 0,18 - 0,35 | 1,00 - 5,00 | 0,35 - 0,60 | 270 |

| 230 | |||||||||

| 210 | |||||||||

| Nodular cast iron | 10 | 210 | 0,20 - 1,50 | 0,10 - 0,12 | 1,00 - 3,00 | 0,18 - 0,30 | 1,50 - 5,00 | 0,35 - 0,50 | 210 |

| 260 | 170 | ||||||||

| 310 | 150 | ||||||||

| Nickle based alloys | 11 | - | 0,20 - 1,20 | 0,10 - 0,12 | 1,00 - 3,00 | 0,18 - 0,28 | 1,00 - 3,00 | 0,30 - 0,42 | 35 |

| 38 | |||||||||

| 65 | |||||||||

| Titanium based alloys | 12 | - | 0,20 - 1,20 | 0,10 - 0,14 | 1,00 - 3,00 | 0,18 - 0,32 | 1,00 - 4,00 | 0,32 - 0,45 | 55 |

| 42 | |||||||||

| Aluminium (Si < 8%) | 13 | - | 0,20 - 5,00 | 0,12 - 0,25 | 0,20 - 5,00 | 0,15 - 0,50 | 800 | ||

| - | 450 | ||||||||

| For Alu group 13 please use Aluline grade PL 05 | |||||||||

| Aluminium (Si > 8%) | 14 | - | 0,50 - 5,00 | 0,12 - 0,20 | 0,50 - 5,00 | 0,15 - 0,40 | 0,50 - 5,00 | 0,20 - 0,60 | 250 |

| For Alu group 14 please use Aluline grade PL 10 | |||||||||