The basics:

Drill Chucks are often connected to a machine's spindle with a removeable Drill Chuck Arbor. The arbor is simply a double-ended shaft of steel, with one end machined to fit up into a machine's spindle, and the other end machined to fit into the back of a drill chuck. A second common type of machine has no removable arbor: the chuck instead mounts directly onto a male projection machined into the spindle itself.

Types of Drill Chucks

Keyed Drill Chucks

- Super Ball Bearing Keyed Chucks: Require a key for tightening or looseningand permit clockwise and counterclockwise turning. The Super Ball BearingChucks are equipped with ball bearings to reduce friction in the tighteningmechanism and provide a better grip on the drill. Used for industrialapplications that include the toughest machining conditions where highaccuracy drilling is not a must (max. run-out .003″ approx.).

- Plain Bearing Keyed Chucks: Equipped with one-piece gearing and sleevethat reduces the possibility of teeth breaking. Used for stationary drilling,turning, milling and wood working machines. For medium duty industrial use.Available with threaded mount for hand held drilling machines and with taperedmounts for stationary drilling machines where run-out is not a problem orfactor (max. .004″ approx.).

- Light Duty Keyed Chucks: Equipped in most power tools for DIY’s fordecades, this is a good, inexpensive chuck for light duty applications.Nowadays they are replaced by keyless chucks more and more. For electrichand held drilling machines, reversible or non-reversible.

- Stainless Steel Keyed Chucks: Manufactured out of stainless steel. For use inthe food, medical and dental industries where tools must be sterilized. Samedesign as a Plain Bearing chuck, but in stainless steel.

- CNC Precision Keyed Chucks w/integrated shank. Ideal for CNC machines.Short design, maximum concentricity, max. run-out .0012″ or better. Highclamping forces, over 75 ft/lbs, and optional through coolant. Permitsclockwise and counterclockwise turning. For use in high speed CNC equipmentfor milling, drilling, reaming and tapping

Keyless Drill Chucks

- Keyless Chucks for High Precision / High Torque applications: Do not requirea key for tightening or loosening. Incorporate a self-tightening feature thatcauses them to grip tighter as more torque is applied. Permit clockwise turningonly. Automatic fitting for efficient, fast change tools. Minimum run-out foraccurate hole sizing, (max. TIR .0016″ or better). For high accuracy drillpresses, jig borers, milling machines and production drilling equipment, CNC′sincluded.

- Keyless Chucks for medium duty applications: Same self-tightening feature asHigh Precision or High Torque chucks but with wider run-outs (about .006″).Automatic fitting for efficient, fast change tools. For medium duty industrial use,available with threaded mount for hand held drilling machines and with taperedmounts for stationary drilling machines. Clockwise turning only.

- Keyless Chucks in Stainless Steel: Manufactured out of stainless steel. Highprecision and self-tightening design. For use in the food, medical and dentalindustries where tools must be sterilized. Clockwise turning only.

- Keyless Drill Chuck for portable drilling machines: These are the latestgeneration chucks for power tools. Does not require a key for tightening orloosening. Some are equipped with a locking mechanism for hammer drillingand also screwdriver operations (clockwise and counterclockwise). Ergonomicdesign, offered with plastic or metal sleeves. For hand held drills, reversible ornon-reversible.

- CNC Precision Keyless Chucks w/integrated shank: Same as type No.5, butkeyless. Ideal for CNC machines but for applications requiring clockwiseturning only as it has a self-tightening feature. Compact construction,maximum connection rigidity, higher precision (TIR .0016″ or better, certifiedby some producers only). For use on CNC machine centers, milling and turningmachines, or other stationary equipment.

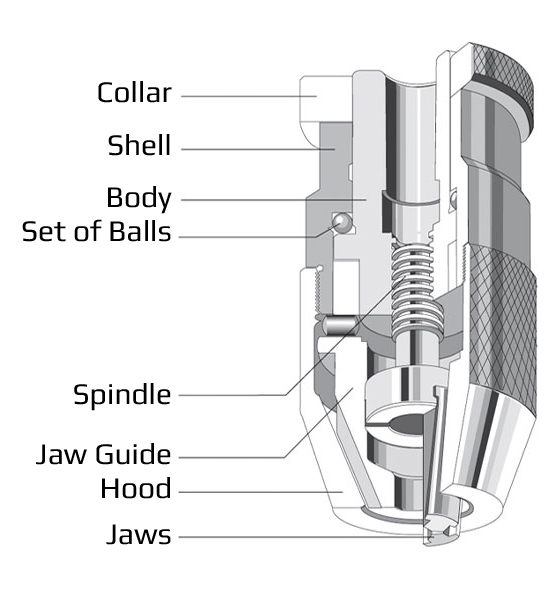

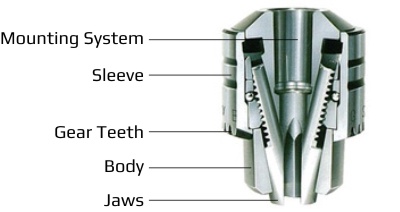

Parts of a Drill Chuck

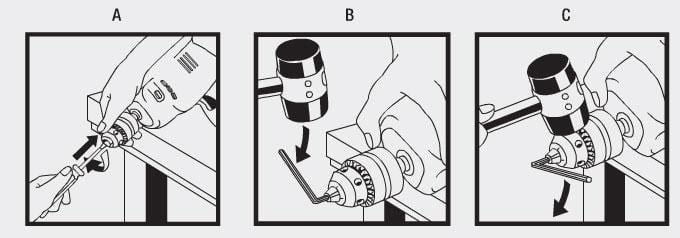

Mounting & Removing Chucks

On Threaded Spindle Portable Tools

Unplug drill or disconnect battery pack. Open jaws of existing chuck completely. Remove left-hand thread screw, if any, from inside chuck and save for re-use (illus. A). Insert hex-type wrench into chuck body and tighten jaws on wrench. Strike wrench counterclockwise with mallet to free and unscrew chuck (illus. B). Screw new chuck onto spindle (clockwise). Insert hex-type wrench in jaws and tighten jaws on wrench. Strike wrench clockwise with mallet several times (illus. C).

On Tapered Shank Arbors

To mount chucks:

Clean both tapers of all grease and grit. With the jaws retracted into the chuck and with the chuck nose resting on a wooden bench, strike the tang of the arbor lightly to seal it into the chuck.

To remove chucks:

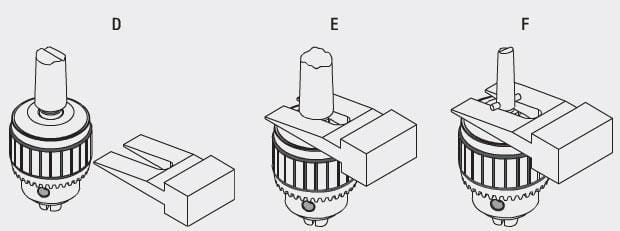

Insert wedge between the back of the chuck and the shoulder of the arbor (illus. D& E). In case the mounting taper of the arbor does not provide a shoulder, a crosshole should be drilled through the neck of the arbor (illus. F) and a cross pin inserted. Then the wedge can be used between the chuck back and the cross pin to free the chuck from the arbor.

For machines with removeable, interchangeable arbors:

To find an arbor/chuck combination that works for a given machine, first identify the type of spindle on the machine. (For instance, a milling machine might have an R8 spindle; a drill press might have a #3 Morse Taper (MT) spindle; a lathe tailstock might hold 2MT tooling.) If you have questions about identifying the spindle of your machine, consult your machine's documentation and/or measure the dimensions of relevant parts and compare them to the reference charts below.

After identification of the machine's spindle, select a chuck. (Choose a chuck based on holding capacity, machine torque, keyed vs keyless, etc.) Note how the selected chuck mounts to the machine's spindle/arbor assembly. Most chucks intended for use on a drill press will mount via a female Jacobs Taper (JT) hole in the back of the chuck. (Some chucks have female-threaded backs instead; these chucks are often used on hand-held drills with threaded spindles.)

With both the machine spindle and drill chuck mount identified, choose an arbor that matches both specifications. For instance, to use a 3JT chuck with an R8-spindled mill, the only arbor that will work is an R8-3JT arbor. To use a 33JT chuck with a 3MT-spindled drill press, the only arbor that will work is a 3MT-33JT arbor.

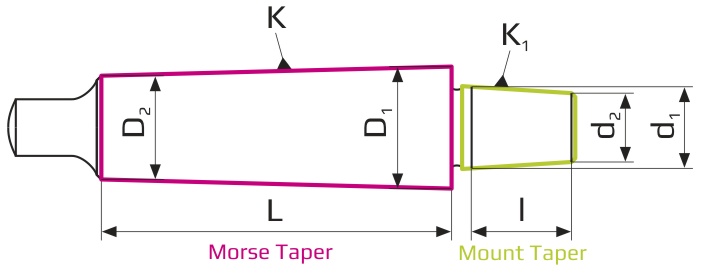

Morse Tapers

| Taper (K1) | Large End (d1) | Small End (d2) | Length (l) | Taper/ Foot | Taper/ Inch | Angle From Center |

|---|---|---|---|---|---|---|

| #0 | 0.3561 | 0.2520 | 2.00 | .6246 | .0521 | 1.4908 |

| #1 | 0.4750 | 0.3690 | 2.13 | .5986 | .0499 | 1.4287 |

| #2 | 0.7000 | 0.5720 | 2.56 | .5994 | .0500 | 1.4307 |

| #3 | 0.9380 | 0.7780 | 3.19 | .6024 | .0502 | 1.4377 |

| #4 | 1.2310 | 1.0200 | 4.06 | .6233 | .0519 | 1.4876 |

| #4-1/2 | 1.5000 | 1.2660 | 4.50 | .6240 | .0520 | 1.4894 |

| #5 | 1.7480 | 1.4750 | 5.19 | .6315 | .0526 | 1.5073 |

| #6 | 2.4940 | 2.1160 | 7.25 | .6257 | .0521 | 1.4933 |

| #7 | 3.2700 | 2.7500 | 10.00 | .6240 | .0520 | 1.4894 |

Jacobs Tapers

| Taper (K1) | Large End (d1) | Small End (d2) | Length (l) | Taper/ Foot | Taper/ Inch | Angle From Center |

|---|---|---|---|---|---|---|

| #0 | 0.2500 | 0.2284 | 0.44 | .5915 | .0493 | 1.4117 |

| #1 | 0.3840 | 0.3334 | 0.66 | .9251 | .0771 | 2.2074 |

| #2 | 0.5590 | 0.4876 | 0.88 | .9786 | .0816 | 2.3350 |

| #2 Short | 0.5488 | 0.4876 | 0.75 | .9786 | .0816 | 2.3350 |

| #3 | 0.8110 | 0.7461 | 1.22 | .6390 | .0532 | 1.5251 |

| #4 | 1.1240 | 1.0372 | 1.66 | .6289 | .0524 | 1.5009 |

| #5 | 1.4130 | 1.3161 | 1.88 | .6201 | .0517 | 1.4801 |

| #6 | 0.6760 | 0.6241 | 1.00 | .6229 | .0519 | 1.4868 |

| #33 | 0.6240 | 0.5605 | 1.00 | .7619 | .0635 | 1.8184 |

B Tapers

| Taper (K1) | Large End (d1) [mm] | Small End (d2) [mm | Length (l) [mm] | Taper |

|---|---|---|---|---|

| #B10 | 10,094 | 9,4 | 14,5 | 1:20,047 = 0,04988 |

| #B12 | 12,065 | 11,1 | 18,5 | |

| #B16 | 15,733 | 14,5 | 24,0 | 1:20,020 = 0,04995 |

| #B18 | 17,780 | 16,2 | 32,0 | |

| #B22 | 21,793 | 19,8 | 40,5 | 1:19,922 = 0,05020 |

| #B24 | 23,825 | 21,3 | 50,5 |